Production Planning and Control (PPC) in-depth

What is Production Planning & Control (PPC)?

Production Planning and Control (PPC) is the “brain” of the manufacturing system. It coordinates all manufacturing activities to ensure that products are produced efficiently.

Definition:

“Production planning is the determination, acquisition, and arrangement of all facilities necessary for future production of products.” — Ray Wild

Meaning:

Planning: Deciding in advance what to produce, when to produce, where to produce, and how to produce. It involves estimating requirements for men, materials, and machines.

Control: Ensuring that execution matches the plan. If there are deviations (e.g., machine breakdown), control mechanisms take corrective action to bring production back on track.

Need for PPC:

Effective utilization of resources.

To achieve production targets (Quality, Quantity, Time, Cost).

To ensure uninterrupted production flow.

The 3 Phases of PPC

PPC operates in three distinct phases:

Planning Phase: This is the thinking stage.

Prior Planning: Forecasting demand, designing the product, and aggregate planning.

Active Planning: Process planning, routing, material planning, and scheduling.

Action Phase: This is the execution stage.

Dispatching: Issuing orders to start production.

Control Phase: This is the monitoring stage.

Progress Reporting: Collecting data on work done.

Corrective Action: Adjusting schedules or capacity to fix deviations.

Steps / Activities of PPC (Functions of PPC)

The main functions of PPC are often remembered as Routing, Loading, Scheduling, Dispatching, and Follow-up.

1. Routing (The “Where” & “How”)

Routing determines the path or route that work will follow from raw material to finished product.

It defines the sequence of operations.

It decides which machine and which department will do the work.

Goal: To find the most economical path.

2. Scheduling (The “When”)

Scheduling determines the time for each operation. It prescribes when work starts and when it ends.

Master Schedule: The overall plan for the factory (e.g., 1000 cars this month).

Detailed Schedule: The daily plan for each machine (e.g., Machine A does welding from 9 AM to 11 AM).

Types:

Forward Scheduling: Starts as soon as possible (Good for rush orders).

Backward Scheduling: Starts as late as possible to meet a due date (Reduces inventory cost).

3. Loading (The “Who” & “How Much”)

Loading is assigning work to specific machines or work centers.

It balances the workload.

It ensures no machine is overloaded or idle.

It matches the job requirements with machine capability.

4. Dispatching (The “Action”)

Dispatching is the transition from planning to action. It authorizes the start of actual production.

Activities:

Assigning work to specific machines/men.

Issuing materials from stores.

Issuing tools and fixtures.

Releasing work orders and time tickets.

5. Follow-up / Expediting (The “Control”)

This is the control tool that keeps a close watch on the progress of the work.

It checks if work is moving according to the schedule.

It identifies bottlenecks (delays) and takes corrective action.

It is the logical step after dispatching.

Tools of Control in PPC

To ensure production stays on track, managers use various tools and techniques:

Dispatching: The primary tool to start work. Without a dispatch order, nothing moves.

Inspection: Checking quality at various stages to prevent wastage.

Expediting (Progressing): Tracking the job’s physical movement to ensure it meets the deadline.

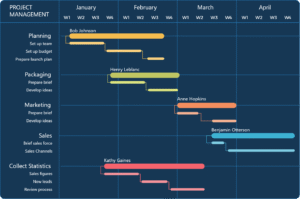

Gantt Charts: Visual charts used to track scheduled vs. actual progress.

5. Control Boards: Visual boards on the shop floor showing machine status (Running/Idle/Breakdown).

Aggregate Planning & MPS

Aggregate Planning: Intermediate planning (3 to 12 months) that balances demand with capacity by varying workforce size, inventory, or overtime.

Master Production Schedule (MPS): A detailed plan that breaks down the aggregate plan into specific end items (e.g., “Produce 50 Red Cars in Week 1”). It drives the Material Requirement Planning (MRP).