Inventory Management: Techniques, EOQ & ABC Analysis

What is Inventory Management? (Concept & Meaning)

Inventory Management is the systematic approach to sourcing, storing, and selling inventory—both raw materials (inputs) and finished goods (products). In business, inventory is considered a necessary evil: too much ties up capital, but too little leads to lost sales.

Why Hold Inventory? (The 3 Motives):

Transaction Motive: To facilitate smooth production and sales operations.

Precautionary Motive: To guard against unpredictable changes in demand or supply (e.g., strikes, transport delays).

Speculative Motive: To take advantage of price fluctuations (e.g., buying bulk when prices are low).

Key Objectives:

Operational: Ensure continuous supply and minimize “stockouts” (running out of stock).

Financial: Minimize the investment in inventory and reduce holding costs.

The Costs of Inventory

To manage inventory, you must balance two opposing costs:

Ordering Costs: The cost incurred every time you place an order (transport, inspection, paperwork). This decreases if you order large quantities less often.

Carrying (Holding) Costs: The cost of keeping stock in the warehouse (rent, insurance, spoilage, theft). This increases if you hold large quantities.

The Goal: Minimize the Total Inventory Cost (Ordering + Carrying).

Techniques of Inventory Control

Managers use specific mathematical models to find the perfect balance.

1. Economic Order Quantity (EOQ)

Concept: EOQ is the ideal order size that minimizes total inventory costs. It finds the “sweet spot” where Ordering Cost = Carrying Cost.

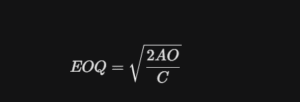

Formula:

A = Annual Usage/Demand (units)

O = Ordering Cost per order

C = Carrying Cost per unit per year

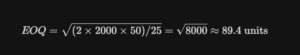

Example: If Annual Demand = 2000 units, Ordering Cost = ₹50, Carrying Cost = ₹25.

2. Reorder Point (ROP) & Safety Stock

Concept: When should you place the next order? You don’t wait until stock hits zero. You order when stock reaches the Reorder Level.

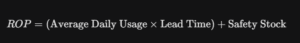

Formula:

Lead Time: The time taken by the supplier to deliver goods after receiving the order.

Safety Stock (Buffer Stock): Extra stock kept to protect against stockouts during emergencies.

3. ABC Analysis (Always Better Control)

Concept: Not all inventory items are equal. This technique classifies items based on their usage value to prioritize control. It follows the Pareto Principle (80/20 rule).

A-Items (High Value): 70-80% of total value, but only 10-20% of quantity. Action: Strict control, low safety stock, frequent ordering.

B-Items (Moderate Value): 15-20% value, 30% quantity. Action: Moderate control.

C-Items (Low Value): 5-10% value, 50% quantity. Action: Loose control, bulk ordering (e.g., nuts and bolts).

Purchasing Methods: Centralized vs. Decentralized

How a company buys materials affects its efficiency.

| Feature | Centralized Purchasing | Decentralized Purchasing |

| Definition | One central Head Office buys for all branches/plants. | Each branch/department buys its own materials independently. |

| Price | Low: Bulk buying gets heavy discounts. | High: Smaller orders mean higher prices. |

| Control | High: Uniform policies and better control. | Low: Harder to monitor total spend. |

| Speed | Slow: Can be bureaucratic and delay delivery. | Fast: Quick response to local needs. |

| Suitability | Organizations with similar needs across units. | Geographically separated units with diverse needs. |